Delivering and Sustaining Improvement

Through Lean Management Techniques

Combining tools and techniques, top down and bottom up, to ensure your Lean activities are successful and most importantly are sustained and continually improved.

Our Process

Capability Build

Through workshops, training and reviews

Problem Solving

By following the 8 Step A3 method for identifying root causes to problems and their countermeasures

Waste Reduction

Through value stream mapping, team engagement and classic 8 Waste analysis

Our clients include

- 50-150 000 people!

- SME to global corporate

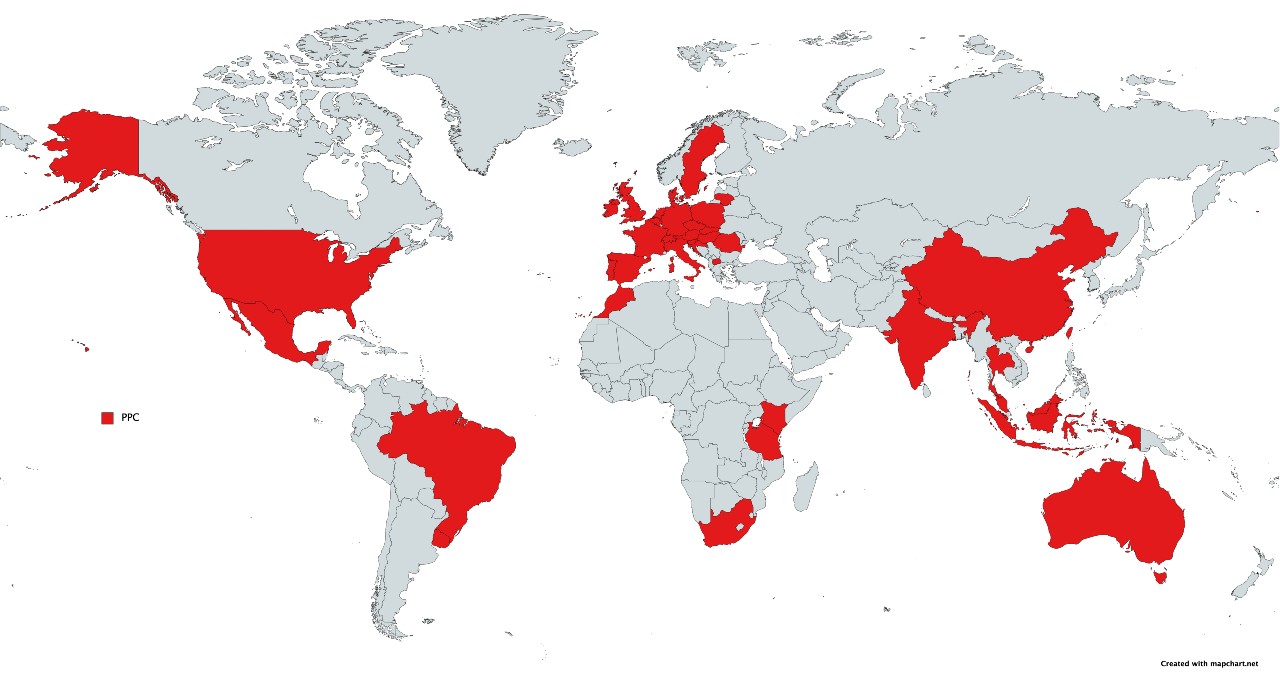

- Geography – local to global

- Sectors:

- Manufacturing – Automotive, Aerospace, FMCG, Pharma, refining, recycling, chemical, food

- Retail

- Transport

- Education

- Medical

Your Bespoke Solution

Tool and Techniques

Training

Engagement and Oversight

Lean Management Projects

Reducing Energy Costs through Operational Excellence

Situation: Energy prices surged significantly in 2021, posing a major challenge to operational budgets. A review of 15 sites, accounting for 80% of the company’s energy usage, revealed opportunities for cost-saving through improved efficiency and operational...

Lean and Green Manufacturing Improvement

Background: A print company was looking to improve their operations using Lean and Green techniques.Situation: During a routine inspection, excessive materials were found in skips, particularly from changeover and splicing reels. A deeper investigation using A3...

Lean and Green Site Continuous Improvement Leaders

Background: The company was keen to develop its Lean capability and deploy continuous improvement across all its European sites. They had no previous skills or ability to deploy training and build their capability.Situation: The company was a high user of material,...

“

With Neil’s depth of experience, he was able to share alternative ways of looking at the challenges,

James Gale

Neil joined us during an extremely busy stage of startup at Cremer UK, where we had just finished installation of the factory and needed to ramp up the facility quickly to deliver customer demand. Despite the challenges of a startup Neil was able to calmly set direction to the teams, ensuring that problems were solved rather than simply contained. With Neil’s depth of experience, he was able to share alternative ways of looking at the challenges, and this was demonstrated during our management team strategy setting sessions. I will gladly work with Neil again in the future, and would recommend him to anyone in need of taking their organisation further on the continuous improvement journey.